Product description:

Microfiber braided string

The price of our Swing Check Valve is subject to fluctuations based on various factors such as specifications, material costs, and currency exchange rates. If you provide me with your contact information, I will be able to provide you with the most up-to-date pricing information. Please note that these changes are normal and are necessary for us to continue providing high-quality products at competitive prices. Thank you for your understanding and support.

How does a check valve work?

Cracking Pressure

The opening of a Swing Check Valve, allowing flow through it, is dependent on a minimum pressure differential between the inlet and outlet, known as the check valve ‘cracking pressure’. It is essential to note that the cracking pressure varies according to the valve design and size. Therefore, it is crucial to verify if your system can generate the required cracking pressure and if it aligns with the specific application's needs.

Closing

In the event that the upstream pressure drops below the cracking pressure or there is a reverse flow from the outlet to the inlet, the check valve will shut off. This is accomplished through a closing mechanism that varies depending on the valve design. Essentially, the gate, ball, diaphragm, or disc is pushed against the orifice by the back pressure, effectively sealing it. Depending on the design of the valve, this closing process can be aided by a spring or gravity.

Installation Orientation

The correct installation orientation is crucial when dealing with one way valves as they only operate in a single direction. You can usually find an arrow on the valve housing indicating the intended flow direction. If not, checking the valve carefully is vital to ensure it is installed in the right direction. If the valve is installed backward, the flow will be blocked, leading to a buildup of pressure that could cause system damage. Therefore, it is essential to observe the proper installation orientation of one way valves.

Check Valve Types

There are various types of check valves available, each functioning differently depending on its design. Among them, the most widely used type is the spring-loaded in-line check valve. In this discussion, we will explore several other types as well.

Spring Loaded In-Line

The in-line spring loaded Swing Check Valve is a prevalent type of valve that has a straightforward design and is easy to understand. A typical example of this valve is shown in Figure 1, while its main components with flow directions are depicted in Figure 2. When fluid enters the valve's input port, it has to exert enough pressure to overcome the cracking pressure and the force of the spring attached. If successful, this action pushes the disc and opens the orifice, allowing fluid to pass through the valve. Conversely, when the input pressure is no longer sufficient or there is backpressure, the spring and the backpressure work together, forcing the disc against the orifice and effectively preventing fluid flow.

One advantage of this valve design is its quick reaction time for closing, thanks to the short travel distance of the disc and the spring's presence. Moreover, because the valve prevents pressure surges, it also helps prevent water hammers from occurring. Various names refer to the in-line spring loaded check valve, including "nozzle check valve" and "silent check valve," among others. It can be installed either horizontally or vertically, but it needs to be fully removed from the line to perform any maintenance or inspection due to its in-line location.

Spring Loaded Y

In-line spring loaded check valves and spring loaded y-check valves work in a similar manner. However, the spring and movable disc in the y-check valve are positioned at an angle, giving it a distinctive 'y' shape. This arrangement allows for easy inspection and servicing while the valve remains connected to the system. It functions just like an in-line valve, but its angled components result in a larger size, occupying more space within the system.

Ball

A ball check valve uses a free-floating or spring-loaded ball that rests on the sealing seat to close the orifice. The sealing seat is normally conically tapered in order to guide the ball into the seat and create a positive seal, thereby, stopping reverse flow. When the pressure of the fluid in the inlet side exceeds the cracking pressure, the ball is dislodged from its seat and allows flow to occur. When the inlet pressure doesn’t exceed the cracking pressure, or there is back pressure, the ball will close with the back pressure or via the spring, effectively closing the orifice.

Figure 4: Spring loaded ball check valve with the inlet port on the left and outlet port on the right.

Diaphragm

Diaphragm check valves consist of a rubber diaphragm that flexes open when the inlet pressure is increased. Normally, these types of valves have a free-floating self-centering diaphragm, which makes them normally open (NO). These means that there is no “cracking pressure”, however, they can be normally closed (NC) and then it requires an inlet pressure to overcome the diaphragms elasticity. Figure 5 on the left shows a normally open diaphragm check valve as there is ‘minimal’ inlet pressure and the media still gets through. As inlet pressure increases, the diaphragm will flex open more allowing flow through, as seen in Figure 5 in the middle. If backpressure occurs (or it is a normally closed diaphragm check valve) the diaphragm will be forced against the opening and seal it to prevent any backflow, as seen in Figure 5 on the right. Due to the normally open nature, diaphragm check valves are ideal for low-pressure or vacuum applications.

Lift

A lift check valve consists of a guided disc that raises (lifts) up off of the valve seat to allow media flow. It requires a cracking pressure to overcome gravity and/or a spring and the guide keeps the disc in a vertical line, so that the disc can be re-seated with the correct alignment and seal. Most commonly, lift check valves require the media to make a 90-degree turn, as seen in Figure 6, but there are lift check valves that are in-line or at an angle. As the inlet pressure decreases below the cracking pressure or there is a backpressure, the valve will close by gravity, spring, and/or by using the backpressure. If there is no spring to assist in closing, mounting orientation in regard to gravity is important to ensure that the disc will swing shut with gravity.

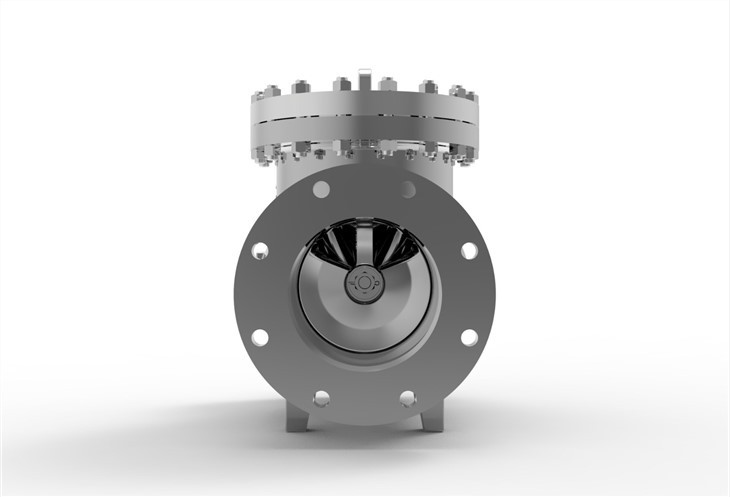

Swing

Swing check valves are also commonly referred to as ‘tilting-disc’ check valves. They consist of a disc that is on a hinge (or trunnion) that swings open with an inlet pressure. As inlet pressure decreases or there is a backflow, the disc will swing shut. If there is no spring to assist in closing, mounting orientation in regard to gravity is important to ensure that the disc will swing shut with gravity. Figure 7 shows an example of a swing check valve.

Stop

A stop check valve is typically a spring loaded y-check valve or a lift check valve, but it has a manual override feature. This allows them to function as a normal check valve and prevent backflow, however, there is an external mechanism that can be used to override it and maintain the valve in an open or closed state. Therefore, this valve can function as two valves in one. They are commonly used in power plants, boiler circulation, steam generators, turbine cooling, safety systems.

Butterfly or Wafer

Butterfly check valves and a wafer check valves can be used interchangeably. They consist of a butterfly, or wafer, style disc that is on a hinge and a spring. When inlet pressure overcomes the cracking pressure, the two sides open, as seen in Figure 9. When the inlet pressure decreases or there is a backflow, the spring on the hinge (or backpressure) will close the disc effectively sealing it. This valve types allows a straight media flow with minimal obstruction.

Check Valves for Water

Check valves are used in numerous water applications, like drinking water and waste water applications, and are simply called one way water valves. For drinking water applications, they ensure that no media from the environment (outlet side of the valve) can enter the system with the safe clean drinking water and contaminate it. For waste water applications, they ensure that the waste water cannot re-enter the system and cause an overflow or additional contamination. For water pumping applications, often times a foot valve is used to ensure no debris will enter the line and to keep internal pressure for priming purposes. Duckbill valves can also be used for discharges on water lines. Sump pump check valves ensure that the discharged water does not come back into the sump pump with gravity when the pump is turned off.

Pneumatic Check Valve

A pneumatic check valve, or air check valve, allows the flow of air in and prevents it from going out. They are often simply just called one way air valves. The most common application is for an air compressor. They allow the compressor to keep certain parts pressurized and other parts de-pressurized. They can be located on a piston compressor (inlet and outlet), air receiver, discharge pipe, etc.

Frequently Asked Questions

What is the check valve symbol?

The check valve symbol can be seen in Figure 13. It points in the orientation that it allows the flow with a vertical line showing it doesn’t allow backflow.

Figure 13: Check valve symbol

What is the purpose of a check valve?

The main purpose of a check valve in a system is to prevent backflow, which could damage equipment or contaminate media upstream.

What are common check valve problems?

Common check valve problems are: noise, water hammer, vibration, reverse flow, sticking, leakage, and component wear/damage. To prevent issues, it is crucial that a check valve is specified correctly for the application and media. The two most common issues due to improper specification are reverse flow and water hammer. For both issues, a fast-closing check valve should be used. Reverse flow can occur if the check valve doesn’t close fast enough and water hammer can occur if pressure surges occur causing shock waves within the media.

Will a check valve stop water hammer?

A check valve can prevent a water hammer if it is fast acting. This prevents pressure surges, which creates shock waves throughout the media. These shock waves can damage equipment, pipe supports, and even rupture pipelines due to the vibration.

What orientation should a check valve be installed?

Check valves need to be installed in accordance to their inlet and outlet, which is often shown as an arrow on the valve housing. As they only allow flow in one direction, if they are installed backwards, they will not work properly. In terms of horizontal or vertical, it depends on your valve design type. If it has a spring, any orientation is okay. If no spring, gravity can affect check valve operation, so ensuring you know the inner components will ensure you install it correctly in a horizontal or vertical manner.

Why is my check valve not working?

When a check valve doesn’t work, it allows backflow. Three possible reasons for this are: sticking, leakage, or slow closing. If there isn’t a filter in the line, dirt or debris can be trapped between the disc and body keeping it open. Due to wear or corroding media on the material, the disc or seat can become damaged or torn preventing a proper seal and allowing backflow. If the valve closes too slow, minimal backflow can enter before a proper seal can occur. Ensure that gravity is helping the design, and/or your spring is quick enough to close the valve rapidly.

Hot Tags: swing check valve, China swing check valve manufacturers, suppliers, factory