Product description:

Microfiber braided string

The price fluctuates due to factors including specifications, the cost of materials, and exchange rates. If you provide me with your contact information, I will keep you updated on the latest pricing. Feel free to rearrange and paraphrase the above information to generate similar content while ensuring it remains faithful to the original text.

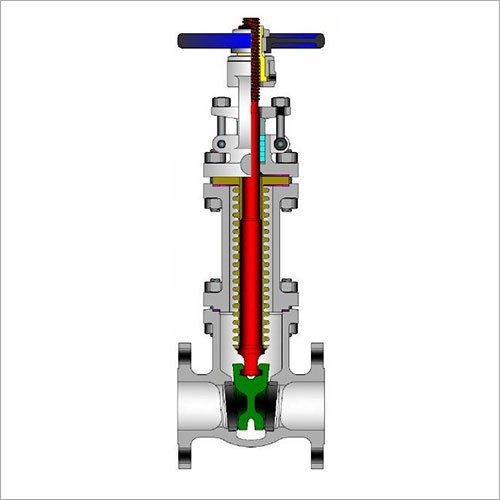

Introduction to Bellow Sealed valves

SUNAWE VALVES is a specialized manufacturer of gate valves with bellows seals. These valves are specifically designed for applications where it is crucial to maintain a hermetic tightness to prevent any potential leakage of hazardous process fluid into the surrounding environment. By utilizing bellows seals, these valves ensure a reliable and secure seal, even in the presence of highly toxic, aggressive, or radioactive fluids. The expertise of SUNAWE VALVES lies in the production of gate valves with bellows seals, offering superior quality and performance for industries that prioritize safety and containment.

For low-pressure applications, valves with large diameters (such as a 48" gate valve) are commonly used, usually in class 300 ANSI.

For high pressure applications, valves with medium-small diameter (ranging from 1/2" to 12") are commonly used, particularly for class 600, 900, 1500, and 2500 ANSI. These valves are designed to withstand high pressure environments and are ideal for a variety of industrial applications. With their robust construction and reliable performance, they are a popular choice for professionals working in industries such as oil and gas, chemical processing, and power generation. Whether you're managing a complex industrial process or handling hazardous materials, these valves offer the strength and durability you need to ensure safe and efficient operation at all times.

The proper construction and assembly of the bellows, as well as its connection to other valve components, play a vital role in ensuring its performance. One crucial aspect is the bellows' ability to withstand fluid pressure on the outside, making it necessary to maintain its resistance.

Our valves are manufactured using high-quality materials required by various services. These include cast or forged carbon steel, low alloy steel, austenitic steel such as AISI 316L and AISI 321, as well as nickel alloys like INCONEL 600 and INCONEL 718. To shape the bellows, we utilize hydroforming techniques. The bellows themselves are typically made from AISI 316L, INCONEL 625, or INCONEL 718.

At SUNAWE VALVES, we prioritize safety and ensure that our bellows seal valves come equipped with a robust packing system. This includes stem packing, serving as a secondary seal. This feature provides an added layer of security to prevent any leakage or potential hazards.

By rearranging the information in the original text, we have generated a similar yet distinct content that highlights the materials used, the manufacturing techniques employed, and the commitment to safety at SUNAWE VALVES.

Our bellows seal valves, manufactured by SUNAWE VALVES, undergo thorough in-house testing to ensure that they meet rigorous standards for preventing fugitive emissions. In particular, we test our valves in accordance with ISO 15848, which involves subjecting the valve to pressurized helium gas.

To simulate real-world use, we pressurize our Gate valve at around 150 Bar before subjecting it to a cycling test. During the cycling test, the valve is repeatedly opened and closed a total of 250 times, both at room temperature and at a high temperature of 400°C. We then use a specialized helium gas leak detector known as a sniffer to detect any helium leakage.

By subjecting our bellows seal valves to these rigorous tests, we are able to ensure that they are among the most reliable and effective valves available on the market. Whether you are looking for valves for industrial or commercial use, you can trust SUNAWE VALVES to provide you with the highest quality products and services.

To ensure leak-free operation, a thorough check is conducted at the emergency stem packing system of bellow seal gate valves where the body and bonnet meet. A vacuum is created in the area to test the packing system and the leakage rates measured at less than 10 at minus six measuring units. Similarly, the body to bonnet joint test is conducted, with leakage rates measured at 50 parts per million. Valves with similar construction for all pressure classes below the one tested and stem dimensions not less than half or above Double of the tested valve are considered qualified by this test.

Creating a safe environment in chemical plants is of utmost importance in today's world. One of the major concerns is the presence of leakage in the pipelines, which leads to emissions. To tackle this issue, plant engineers need to be vigilant in detecting and noting down any leakage points using different methods and instruments. The critical areas prone to leaks include flanged gasket joints and the Valve/pump gland packing. It is essential for process engineers to prioritize environmental protection and design plants that minimize the release of toxic chemicals. The chemical process industry is actively adopting safer technologies to ensure a sustainable future.

The maintenance or plant engineer is typically concerned about leakage from the valve gland or stuffing box. This type of leakage can cause various issues and should be addressed promptly.

a) Pollution to the atmosphere b) Loss of material c) Risk to plant employees

Let's discuss the case of a leakage caused by steam passing through the Valve gland. When the pressure is at 150 PSI, even a minuscule clearance of just 0.001" within the gland can result in a significant leak, amounting to approximately 25 pounds per hour. This translates to a financial loss of about USD 1.2 per eight-hour shift or USD 1,100 per year. Similarly, if there is a small drop of 0.4 mm in diameter every second, it can lead to a wastage of approximately 200 liters of expensive oil or solvent annually. However, the utilization of a bellow seal Valve can effectively reduce such leakage. Now, let's delve into the construction and functionality of the bellow seal Valve.

Bellow construction

The bellow cartridge is welded to both the Valve Bonnet and the Valve stem. The bellow cartridge has a number of convolutions and these convolutions become compressed or expanded depending upon the movement of Valve stem. (Scientifically speaking the bellow gets compressed when the Valve is in the open position and expanded when the Valve is in the closed condition). It is important to properly install the Valve bodies. The bellow can be sealed to the Valves in two different ways. Firstly, the bellow can be welded to the Valve stem at the top and the Valve body on the bottom. In this case the process fluid is contained inside the bellow or in second method the bellow is welded to the Valve stem at the bottom and the body on the top. In this case the process fluid is contained in the annular region between the Valve Bonnet and bellow (from the outside).

The bellow is a critical component and forms the heart of the bellow seal Valves. To avoid any twisting of the bellow the Valve must have a stem with linear movement only. This can be achieved using a so-called sleeve-nut at the Yoke portion of the Valve Bonnet. A handwheel is fitted onto the sleeve-nut which effectively transfers a rotary motion of the handwheel into a linear motion in the Valve stem.

Bellow types

There are two main types of bellow: the Forged Bellow and the Welded Bellow. Formed-type bellows are made from rolling a flat sheet (thin wall foil) into a tube which is then longitudinally fusion welded. This tube is subsequently mechanically or hydrostatically formed into a bellow with rounded and widely spaced folds. The welded leaf type bellow is made by welding washer-like plates of thin metal together at both the inner and outer circumference of the washers - like plates. A welded leaf bellow has more folds per unit length as compared to forged bellows. Thus, for the same stroke length, forged bellows are two to three times longer than their welded leaf counterparts.

Reportedly, mechanically forged bellows fail at random spots, while the welded leaf usually fails at or near a weld. To ensure full penetration of bellow ends and end coller welding it is advisable to fabricate using micro plasma welding.

Bellow design

The multi-ply bellow design is preferred for handling higher pressure fluids (generally two or three plies of the metal wall). A two ply bellow can increase its pressure rating by 80% to 100% as compared to a single ply bellow of the same thickness. Alternatively, if a single ply bellow of a thickness equivalent to a pressure rating of a two ply bellow is used, the stroke length is reduced. Thus, a multi-ply bellow design offers a distinct advantage over a single ply bellow. It is clear that the bellow is subject to metal fatigue and this fatigue can induce weld failure. The bellow fatigue life is affected by the material of construction, fabrication technique, stroke length and stroke frequency, in addition to the usual parameters such as fluid temperature and pressure.

Bellow materials

The most popular stainless steel bellow material is AISI 316Ti which contain Titanium to withstand high temperatures. Alternatively, Inconel 600 or Inconel 625 improve fatigue strength and corrosion resistance as compared with stainless steel bellows. Similarly, Hastalloy C-276 offers greater corrosion resistance and fatigue strength than Inconel 625. Fatigue resistance can be improved by using a multiply bellows system and reducing the stroke length; this can significantly increase the bellow service life.

Valve options

The most common Valve types to be fitted with bellow seals are the gate and globe designs (see Figure 1).These are very suited for use with bellows due to their internal construction and axial movement of the Valve stem.

Based on available information, it seems that current bellow seal Valves range in size from 3 mm NB to 650 mm NB. Pressure ratings are available in from ANSI 150# to 2500#. Material options for the Valves include carbon steel, stainless steel and exotic alloys.

Applications

Heat Transfer media: hot oil is commonly used in industries such as synthetic fibres / POY (Partially Oriented Yarn). However, there is always a risk of fire due to hot oil spillage on highly inflammable chemicals. Here, bellow seal Valves can stop the leakage.

Vacuum / ultra high vacuum: some applications require a vacuum pump to continually extract air from a pipeline. Any conventional Valves installed on the pipeline can allow external air to enter the pipeline thorough the Valve stuffing box. Hence the bellow seal Valve is the only solution to prevent air from passing through the stuffing box.

Highly hazardous fluids: for media such as chlorine (see Figure 2), hydrogen, ammonia and phosgene, the bellow seal Valve is an ideal design as leakage through the gland is totally eliminated.

Nuclear plant, heavy water plant: in instances where radiation leakage is to be prevented at all times, the bellow seal Valve is the ultimate choice.

Costly fluids: in some applications leaks need to be avoided simply because of the high cost of the fluid. Here, an economic assessment often favours the use of bellow seal Valves.

Environmental standards: around the world, standards regarding emissions and the environment are getting more stringent day by day. It can therefore be difficult for companies to expand within existing premises. With the use of bellow seal Valves, expansion without additional environmental damage is possible.

We are a professional Bellow Seal Gate Valve manufacturers in China. We can provide the best Bellow Seal Gate Valve for sales and competitive price. If you are looking Bellow Seal Gate Valve supplier, we are a good choice. Contact us to buySoildBellow Seal Gate Valve.

Hot Tags: bellow seal gate valve, China bellow seal gate valve manufacturers, suppliers, factory